Applications and Industries

Injection molding services give manufacturers like Premier Plastics the flexibility to produce an extremely wide range of unique products. From fairly standard or stock components to highly customized designs, from simple parts to highly complex assemblies, injection molding can do it all efficiently and cost-effectively.

Our company specializes in providing commercial and industrial injection molding services that are adaptable and scalable for the widest range of products possible. From design, development, and prototyping to production molding and final assembly, our in-house engineering team works closely with you to meet all of your manufacturing needs.

Injection Molding Service Versatility Since 1983

As one of America’s leading plastics manufacturers for more than four decades, Premier has served an exceptionally diverse range of injection molding industries and product applications.

Our primary experience has centered around serving the automotive, agricultural, aviation, construction, energy, and medical device sectors. In the realm of consumer products, our company has developed quality injection molded plastics for the home improvement niche, healthcare devices, sports and recreational equipment, as well as toys and learning products.

Below, we take a closer look at some of today’s various industries and diverse product applications that rely on the injection molding process.

Common Uses for Injection Molding Services in Commercial and Industrial Applications:

Automotive Parts

FPlastic injection molding is used extensively throughout today’s automotive manufacturing space. The versatility of the process makes it suitable for molding many different car parts such as interior trim pieces, dashboards, door panels, exterior body panels, bumpers, and even some drivetrain components.

Modern automotive plastic parts are complex and typically require relatively high precision combined with high durability. Injection molding tends to be the best manufacturing solution to deliver these qualities at a relatively low cost per part.

Consumer Electronic Devices

Many plastic parts of consumer electronic devices are injection molded because they demand a cost-effective, highly repeatable production process. Common injection molded consumer electronics include device housings and enclosures as well as buttons, switches, and connectors. Injection molding allows for intricate designs, precise dimensions, and the integration of features like snap fits and hinges, making the process ideal for producing ergonomic and functional electronic devices. With Premier’s integrated prototyping solutions, injection molding also offers a streamlined method for testing out different ergonomic designs.

Household Products

From kitchenware to office supplies, plastic injection molding is behind many everyday household items. For example, we can manufacture custom molded storage containers, utensils, appliance components, and furniture fittings. The process enables mass production of cost-effective, durable, and aesthetically pleasing products that enhance convenience and functionality in homes and offices.

Molded Plastic Packaging

Plastic injection molding is widely used in the packaging industry for manufacturing containers, caps, closures, and other packaging components. It offers versatility in design, allowing for customized shapes, sizes, and features to meet specific product requirements. Injection-molded packaging can range from small, intricate items like bottle caps to large, durable containers for industrial use.

Injection Molded Industrial Components

Injection molding is a crucial service for producing many modern industrial components. Applications include heavy-duty plastic components as well as metal replacement parts. For example, there are use cases in which we can mold traditionally metal industrial components such as gears, bearings, valves, and enclosures using high-strength plastic materials.

Industrial equipment generally requires a combination of high strength, chemical resistance, and dimensional/thermal stability. Engineering-grade plastics and other high-performance materials can achieve these qualities reliably when combined with Premier’s precision injection molding process.

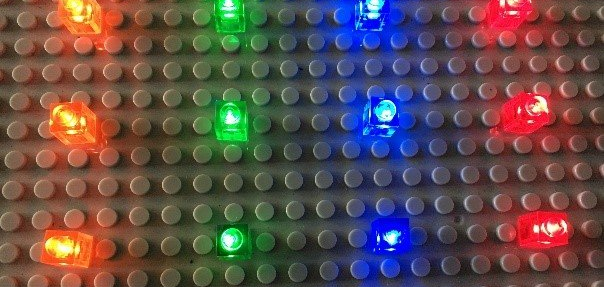

Plastic Toys and Youth Learning Tools

Plastic injection molding is instrumental in the toy and game industry for producing a wide range of products, including action figures, puzzles, building blocks, and board game pieces. The process enables the mass production of colorful, durable, and intricately detailed toys that captivate children and adults alike.

Check out our Case History Page for an overview on one of our custom injection molding projects for Fat Brain Toys.

Some of the most common injection molded plastic products include:

- Automotive Components – Such as interior trim, dashboards, door panels, bumpers, grilles, and exterior body panels.

- Bottle Caps and Closures – Used for sealing bottles containing beverages, pharmaceuticals, cosmetics, and various other liquids.

- Consumer Electronics Parts – Such as housings, buttons, connectors, cases, and structural components for devices like smartphones, laptops, and cameras.

- Containers, Packaging, and Inserts – Including food containers, cosmetic jars, storage bins, and blister packs used for retail packaging, as well as protective inserts and trays used for shipping delicate items.

- Household Products and Appliances – Kitchenware such as utensils, containers, and storage bins, as well as handles, knobs, control panels, and other parts for household appliances like refrigerators, washing machines, and dishwashers.

- Toys, Games, and Learning Tools – Action figures, dolls, building blocks, board game pieces, puzzles, and various other plastic toys.

One of the Midwest's Leading Injection Molding Companies Since 1983

Located in Omaha, Nebraska, Premier Plastics is backed by more than four decades of providing quality American injection molding services. Today our company is one of the Midwest region’s premier plastic molding companies serving a wide range of industries and applications. Premier is an ISO 9001:2015 certified manufacturer committed to delivering your products accurately, on-time, and exactly according to your specifications.

Share On: